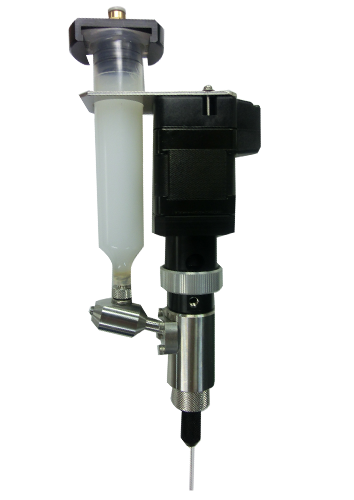

液体定量吐出バルブ バルペットSB-110ⅢS

○高精度スクリューバルブディスペンサー

- 高粘度液剤を効率よく高速に吐出可能です。

The high viscosity liquid can be efficiently dispensed at high speed. - スクリュー軸の回転制御で高精度の吐出が可能な為、繊細な点及び線塗布が行えます。

Thanks to the rotation control of the screw shaft, you can get a high precision dispensing to a delicate point and lines. - 吐出効率が大幅にUP。(従来品と比べて最大2.5倍の効率UP)

The dispensing efficiency rises greatly.(Max 2.5 time dispensing efficiency has improved compared with old goods. ) - エアー、液だまり、発熱量も大幅に削減。

The place where air and the liquid collect has been decreased greatly, and the calorific value has been reduced,too. - 接液部と駆動部の接続は袋ナット方式を採用。メンテナンス性も大幅に向上、さらに使いやすくなりました。

This model has adopted cap-nut method, so you can maintain easy. - 専用の交換式スクリューライナーを設け、吐出バラツキの改善、耐久性と消耗部品の低コスト化を高次元で両立させました。

Because the screw liner of the exchange type was adopted, the improvement of the stability, the improvement of durability, and lowering the cost in wear-out parts were able to be done. - スクリュー式ディスペンサーの新たなベンチマークモデルです。

This is a new benchmark model at a screw type dispenser.

| 最適使用液 Suitable liquid material |

エポキシ(Epoxy)、シリコン(Silicone)、グリス(Grease)他 |

|---|---|

| 適応粘度Applicable viscosities | 30,000~500,000mPa・s |

| 液加圧方式Fluid pressurizing method | 同期加圧(Synchronous) or 常時加圧(Always) |

| 材料圧送圧Material feed pressure | MAX0.5MPa |

| 駆動方式Dispensing screw driving method | ステッピングモーター(サーボ制御)(Stepping motor Servo control) |

| モーター回転数Motor rotation speed | 6~1,500rpm |

| モーター電源Motor power | DC24~48V |

| モーター分解能Motor resolution | 0.72°/PULSE (500P/R) |

| 外形寸法Externals dimensions | W71.5×D42×H205 |

| 重量Weight | 約770g |

| 吐出量Dispensing volume | 0.0001ml~連続 |

| 用途Use | 電子基板にクリーム半田及び銀ペースト材精密塗布 電子部品に高粘度接着剤微細塗布など |

| 備考Remarks | ノズルは、別売と成ります。 |

データ送付受付フォーム

下記タブで送付データをCADデータか取扱説明書に変更できます。

CADデータ送付受付フォーム

会社名、ご担当者名、電話番号、E-mailをフォームからお送りいただくことで、本商品のCADデータを送付いたします。下記フォームに必要事項をご記入の上送信下さい。

※IPアドレスを記録しております。いたずらや嫌がらせ等はご遠慮ください

SB-110ⅢS取扱説明書送付受付フォーム

会社名、ご担当者名、電話番号、E-mailをフォームからお送りいただくことで、本商品の取扱説明書データを送付いたします。下記フォームに必要事項をご記入の上送信下さい。

※IPアドレスを記録しております。いたずらや嫌がらせ等はご遠慮ください

copyright(C)2013 ACE-GIKEN co.,Ltd Allright Reserved.